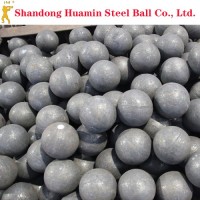

Product Description

High chrome grinding ball is the alloy steel grinding media by casting, was used to Ball mill / SAG mill / Tower mill for Mining & Cement and other industries. This alloy material have 10% - 28% Chromium, finished product hardness can reach to min HRC 58 & max HRC 65, so this high chrome grinding ball consumption will much less than forged /hot-rolled steel ball and low chrome cast steel ball, ball consumption unit cost is the best of all kind material grinding media.

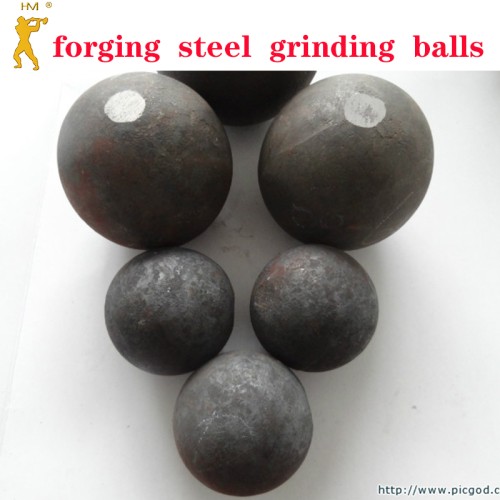

Detailed photo

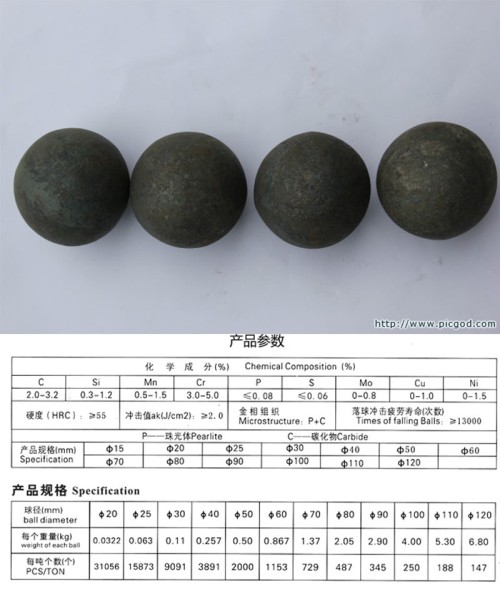

Alloy Chemical Composition:

Product Physical Technical:

Product Weigth : | ||||||||

Size (mm) | Φ20 | Φ25 | Φ30 | Φ40 | Φ50 | Φ60 | Φ70 | Φ80 |

Weight (kg/pcs) | 0.034 | 0.063 | 0.11 | 0.26 | 0.51 | 0.86 | 1.37 | 2.05 |

Q'ty (pcs) per mt | 31506 | 15873 | 9091 | 3891 | 2000 | 1153 | 729 | 487 |

Size (mm) | Φ90 | Φ100 | Φ110 | Φ120 | Φ125 | Φ130 | Φ160 | |

Weight (kg/pcs) | 2.9 | 4.0 | 5.3 | 6.8 | 7.75 | 8.74 | 13.5 | |

Q'ty (pcs) per mt | 345 | 250 | 188 | 147 | 129 | 114 | 74 | |

Company introduction

Company introduction

Shandong Huamin Steel Ball Co., Ltd. is a professional production of wear-resistant steel ball and wear-resistant steel grinding rod enterprises. The founder of the company began to engage in wear-resistant steel ball business in 1986, with forged steel balls and cast steel balls of two bell categories, the company has more than 30 years of forged steel balls and casting grinding ball production experience.

The company is located in Zhangqiu Industrial Park, Jinan, Shandong Province, 300 kilometers from Qingdao Port and 30 kilometers from Jinan Airport. Our factory covers an area of more than 10,000 square meters. The production capacity of forged steel balls is 200,000 tons, and the annual production capacity of the foundry is 30,000 to 50,000 tons.

Production technology and advantages

Huamin steel balls not only has a large production capacity and advanced production equipment, but also is equipped with advanced design & testing equipment, such as Auto-CAD drawing software, CNC model cutting machine, direct reading spectrometer, hardness tester, far infrared thermometer, etc., which can help accurately control models size and alloy composition, realize temperature controlled melting, constant temperature pouring, automatic temperature controlled quenching/annealing and other production processes, ensuring the stable and reliable quality of grinding balls & casting parts.

Serving many countries around the world

Serving many countries around the world

Huamin steel balls have more than 30 years of experience in the design/ produce and after-sales service of grinding media and wear-resistant casting parts. we have rich experience in cooperating with enterprises in different industries such as iron ore/non-ferrous metal mines/cement industry/sand & aggregate industry/Concrete materials and coal-fired power plants, and provide solutions for end customers. NGZR can do OEM & ODM with customer, our products are not only hot sale in China domestic market, also been exported to oversea countries such as the Philippines/ Malaysia/ Indonesia/ Ghana/ Zimbabwe, etc.

Create a brilliant future together

Huamin is committed to providing one-shop solutions for the grinding media and wear-resistant casting parts used in customers' existing equipment, reducing unit production costs & improving production efficiency for customers,, ensuring and extending the maintenance cycle and service life of customers' equipment, creating value for customers, to take NGZR own development.

通过

通过